Integrated Energy and Resources Recovery

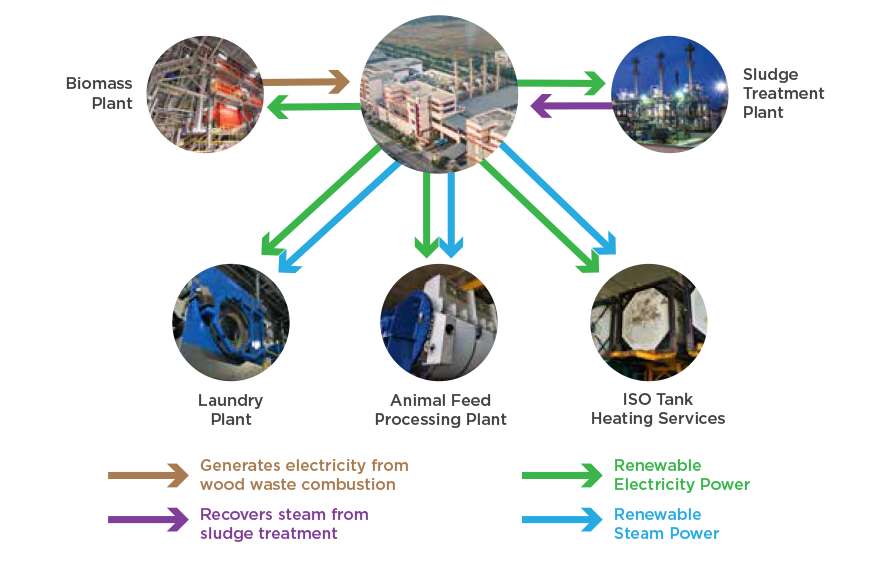

800 Super has invested over $130 million to build the Self-Sustaining Integrated Energy and Resources Recovery Facility, which features an integrated, self-sustaining energy ecosystem for multiple business activities. The 21,000-square-metre integrated facility, which is about the size of three football fields, currently houses a Biomass Plant and a Sludge Treatment Plant, as well as an Industrial Laundry Plant. The facility efficiently recovers the waste energy of one business activity to generate renewable energy for the next. This effectively reduces pressures on the environment by processing waste, recovering resources and channelling them back into production.

New Business Offerings

With the state-of-the-art facilities, 800 Super is leveraging its capabilities and resources to expand into two new synergistic business lines, namely, animal feed and sterilising processing, and heating services for third-party ISO tank containers. The new businesses will be housed within the Tuas integrated facility, and powered by both electricity generated from 800 Super’s Biomass Plant, and steam produced by its Sludge Treatment Plant.

800 Super has also launched its animal feed processing business, which converts wet spent grains such as malt and soybeans into animal feed ingredients. This is done by a steam-driven heat-drying and sterilisation process, with steam being supplied from the Sludge Treatment Plant. In due time, processing capacity will be doubled from an initial 240 tonnes of spent grains per day to 480 tonnes by end-2020.

Finally, 800 Super is also introducing heating services for third-party ISO tank containers by further tapping into the renewable steam power produced by the sludge treatment process. By using the steam produced efficiently, 800 Super enjoys cost savings from not relying on other conventional fuel sources like diesel. The two new business lines reflect 800 Super focus on harnessing renewable electricity and steam produced within its self-sustaining integrated facility.